The Rolls-Royce of Tours

Engineer Henry Royce set out to create the pinnacle of luxury car experience in 1903. His passion soon attracted the sales and marketing talent of Charles Rolls. Together, they launched the Rolls-Royce Motor Company, and now, 122 years later, the brand defines the ultimate car experience and the very definition of quality itself. The ultimate accolade is to be the ‘Rolls-Royce of‘. An invitation to their manufacturing plant in Goodwood, West Sussex, is an opportunity I’m eager to take.

Rolls-Royce is minutes from the charming Chichester village. The campus, built in 2003, is located on a corner of the extensive Goodwood Estate, owned by, lover-of-all-things-automotive, the Duke of Richmond. The land also plays host to Goodwood’s eponymous Revival and Festival of Speed. Manicured lanes and box-cut trees await as you glide past the pool, apiary and occasional pheasant. The car park is full of Rolls-Royces, BMWs, and the MINI I’m driving. I’m not out of place; BMW owns all three brands.

With a quarter of an hour until my appointment, I drift into the reception and register. My host for the morning is also early. Marius Tegneby is Head of Global Luxury and Corporate Communications. Norwegian of origin, BMW Group by training, in his element at Rolls-Royce; he loves his work with a collected Northern European focus.

A Rolls-Royce is not off the shelf: no car is the same. The acquisition process itself is an amazing journey. Customers work through a design process, either here in Goodwood or in the global network. A build process can take anywhere from months to years, depending on how exacting a client wishes to be. Anything can be done. Nothing is off limits. Marius takes me through the design journey with a barista coffee in the study annex of the customer experience lounge.

From here, customers work with a designer to specify their ultimate car. Every design option is available, every leather, every colour combination can be created with models. One room is dedicated to exterior design, and small models enable the imagination. A second room offers interior ‘atelier’ options. Customers move through the process, Rolls-Royce covers every imaginable option, plus more that the client hasn’t thought of. Everything can be specified: from custom monograms to bespoke wood veneer artwork, to laser night sky roofs replete with shooting stars.

For the second part of the tour I don a regal purple safety jacket and we step from the corporate end of the building to the plant like none you have before experienced. It’s close to silent, no sound of heavy machinery. Just footsteps and calm voices. People know the plan. It’s calm. They care.

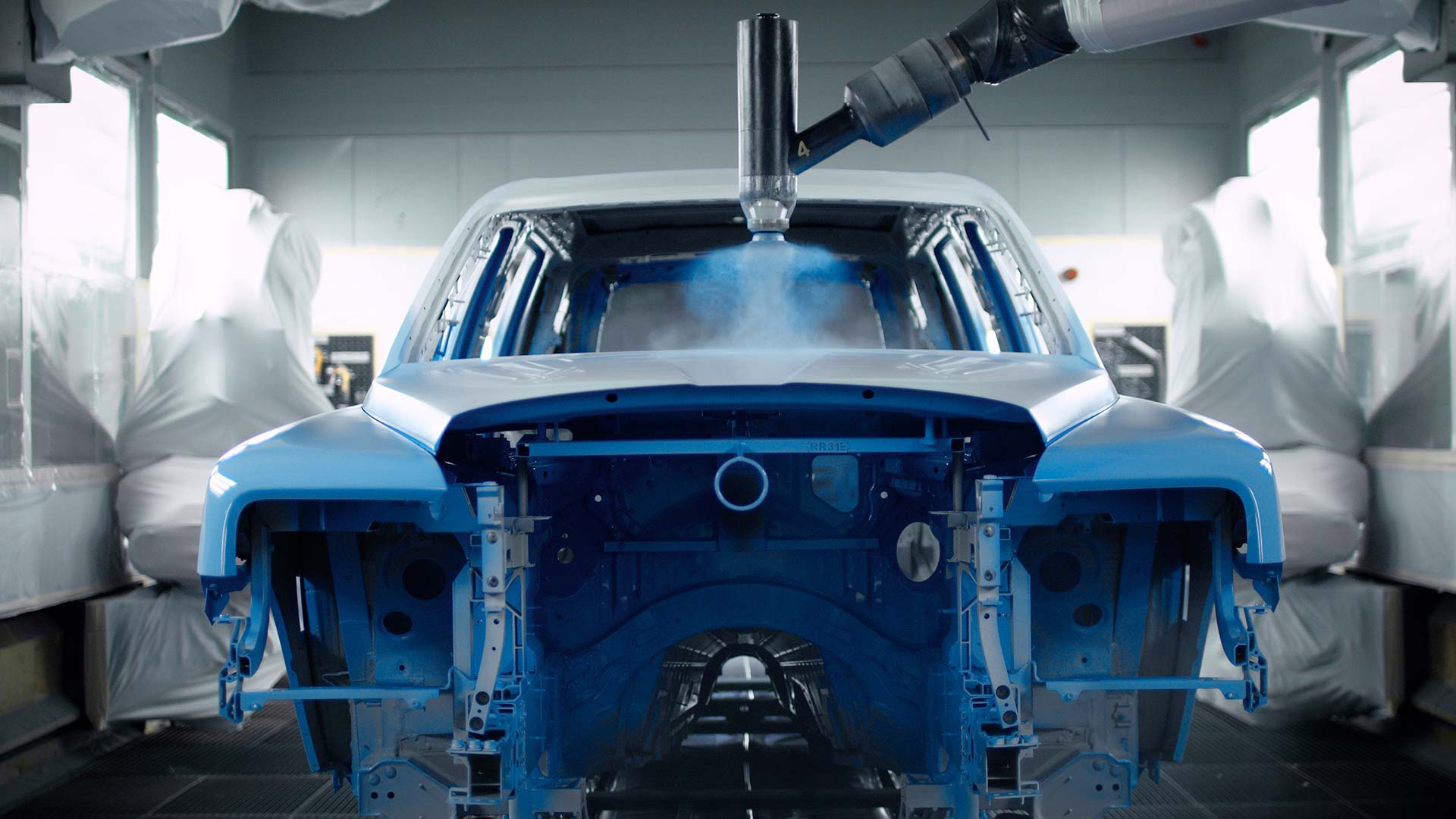

Manufacturing of engines and bodies utilises the BMW plant network. The car bodies are built at the BMW Group Plant Dingolfing, close to Munich. The first stop here is the paint shop. The famous V12 engine is manufactured at BMW’s Hams Hall plant near Birmingham. Goodwood assembles the drivetrain and merges everything into the body.

Fully assembled, painted bodies progress through the awaiting engineers and artisans at each station staffed by specialists who oversee each function. The majority of detail work is done in-house. No fewer than seventeen people weave fibre optics into ceiling panels. A temperature-humidity-controlled thermador room keeps wood veneer conditioned for artisans to fashion into any part that may be inlaid. Nearby, a massive machine embroidery table stitches monograms. Expert eyes analyse for perfection. Every step is allocated ample time. No rush. Things must be right.

I’m here in an auspicious year. 2025 marks an incredible 100 years of the range-topping Phantom, and there is no more storied vehicle. Queen Elizabeth II was ferried to her wedding in a Phantom. John Lennon bought a black one and then painted it. Elton John gave one to his percussionist. Marlene Dietrich had one, Elvis loved his, and so did 50 Cent. To celebrate its centenary, Rolls-Royce is unveiling an exclusive 25-car collection featuring its most intricate woodwork. The Blackwood interior door veneers form the canvas for the design of maps, landscapes, and floral elements, using laser-etching at multiple depths. Expert hands apply fine patterns using textured ink layering, then marquetry adds sculpted, engraved motifs on top of the main surface, and 24-carat gold leafing is hand-laid into the design. It results in a new form of automotive wood sculpture. It’s something to behold – it belongs in a gallery.

Rolls-Royce represents true luxury. Perhaps it defines luxury. Creating the world’s most recognised and desirable handcrafted products for its international clientele is no easy feat. When the facility in Chichester was created, there was plenty of space. With the success of the brand, every corner of the original building is filled. Over 2,500 people work here at the global headquarters and manufacturing plant, where Phantoms, Ghosts, and Spectres are crafted, perfected – and inspire greatness.