Offices That Move

I have always had a fascination and great interest in how people past, present and future work in offices. Forty years ago I formed a company whose main purpose was to transform New Zealand office work by encouraging office management to discard their private partitioned offices and move into a landscaped office format dubbed “burolandschaft” pioneered by the Quickborner Team in Hamburg, Germany.

These principles saw the proliferation of office layouts with desks divided by plants and low height screens rather than austere walls which severed communication and collaboration followed by the era of the office cubicle or workstation which tended to re-build barriers between workers once again.Now we have come full circle with the latest activity based workplace (ABW) thinking which once again promotes collaboration with fluidity and flexibility resulting from the mobility that technology and IT advances have provided.

Now we have come full circle with the latest activity based workplace (ABW) thinking which once again promotes collaboration with fluidity and flexibility resulting from the mobility that technology and IT advances have provided.

Germany have often been at the forefront of new thinking in office layout and anything produced there is always characterised by a certain rigor underlying the excellence – no wonder their balance of trade is so great.Following on from these traditions is Wilkhahn, Germany’s premier manufacturer of office and conference furniture. Over sixty years ago, the company made better utility value, long lasting

Following on from these traditions is Wilkhahn, Germany’s premier manufacturer of office and conference furniture. Over sixty years ago, the company made better utility value, long lasting design and durability its goals. Wilkhahn’s classic office chair FS-Line (1980) Confair folding conference table (1994) Modus office chair (1994) and Aline skid-base chair (2004) are all important milestones in the development of the modern office.

Following on from these traditions is Wilkhahn, Germany’s premier manufacturer of office and conference furniture. Over sixty years ago, the company made better utility value, long lasting design and durability its goals. Wilkhahn’s classic office chair FS-Line (1980) Confair folding conference table (1994) Modus office chair (1994) and Aline skid-base chair (2004) are all important milestones in the development of the modern office.

The Confair conference table quickly became ‘the’ table when it was released and has remained so – it marked the beginning of the moveable flexible workspace which underpins the new thinking on activity based work. Smooth, easily operated and locked in mechanisms enabled two people to not only fold, move and assemble large tables from one space to another but to change table sizes instantly with no brains or brawn required.

Seating at mobile spaces also needed to be revolutionised and the design of office chairs also required a game changing development, which Wilkhahn have patented and called trimension technology. Trimension enables forward and backward tilts as well as rotational movement and sideways tilting, enabling it to move like a second skin as the sitter changes posture throughout the day. The chair uses the principles of how the body is made: hip joint, knee joint and swinging arms. So if you lean sideways, your chair seat follows your body.

With office workers increasingly sitting side by side at tables and workbenches this sideways tilt has become an essential part of ergonomic health in the workspace and the latest examples of these pioneering innovations are the multi purpose, three dimensional ON and IN multi purpose task chairs.

The cool sporty look of the IN chair, however, is not just a visual effect – it came from technologies that really are applied to sportswear and sports cars. The surface of IN’s backrest is made of a form-fit knit called 3D Formstrick – a technology used in developing trainers in order to integrate different strengths and thicknesses directly into the material. The seat shell and back are connected with the rest of the chair via joints to help the body maintain its centre of gravity.

The cool sporty look of the IN chair, however, is not just a visual effect – it came from technologies that really are applied to sportswear and sports cars. The surface of IN’s backrest is made of a form-fit knit called 3D Formstrick – a technology used in developing trainers in order to integrate different strengths and thicknesses directly into the material. The seat shell and back are connected with the rest of the chair via joints to help the body maintain its centre of gravity.

The shell is made as one single piece using two component technology from the automotive industry. In the cockpit of a car, you need more soft material but the surface has to be high quality. In the past, you covered it. Now you do it in one step and with this technology, you can implement the fibreglass reinforcement where you need it and flexibility where you need it.

The recently designed Occo chair and table by jehs+laub enables individuality and versatility in the workplace by offering seventy two different options including legs, colours and cushioning, within the distinctive cut out shell design. The shell can be read as an ‘O’ from the front or back, hence the name but more than that, the cut out shape was designed to minimise the chair’s weight to enable stacking. Wilkhahn’s stacking mechanisms have a beauty all their own – ease, functionality and safety are seamlessly integrated so that one person can do all the work. The sculptural shape of the chair itself, with varied shell thickness enables comfort, stability and flexibility.

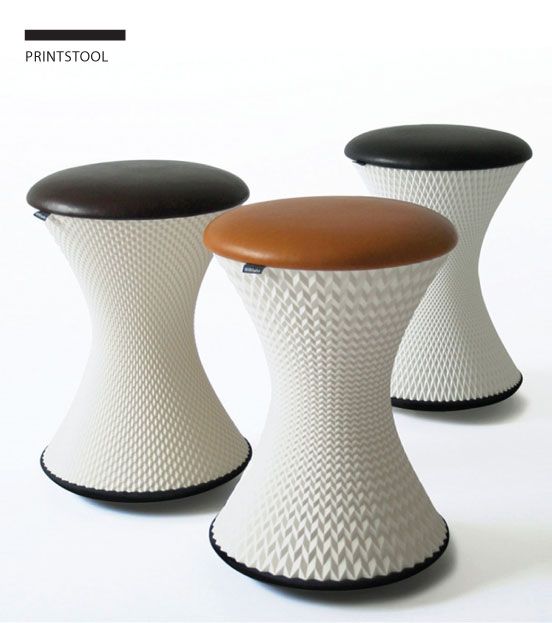

Wilkhahn is also the first furniture manufacturer worldwide to produce ready–to-use, 3D printed furniture. In the office furniture industry, their PrintStool One places the company at the forefront of a manufacturing method that allows the role of producer and consumer to merge. Once customers send their printing jobs, they control production and can become co-designers who define structures, shapes, colours and sizes. The results are simply sent as data sets to 3D printers that produce the stools within just a few hours.

Wilkhahn is also the first furniture manufacturer worldwide to produce ready–to-use, 3D printed furniture. In the office furniture industry, their PrintStool One places the company at the forefront of a manufacturing method that allows the role of producer and consumer to merge. Once customers send their printing jobs, they control production and can become co-designers who define structures, shapes, colours and sizes. The results are simply sent as data sets to 3D printers that produce the stools within just a few hours.

Wilkhahn’s investment in this development project shows that the company is a true pioneer where this technology is concerned as has been the case in previous decades. What truly stands out however is the smooth way in which a lock or furniture join clicks into place like the door of a finely engineered German automobile – you know that it is engineered for a lifetime with workmanship that you can truly trust.

Alan Bertenshaw of Matisse International Design. Read his columns at M2now.co.nz. matisse.co.nz